Perform an initial analysis using what seems to you to be a "reasonable" mesh. Reanalyze the problem using twice as many elements in critical regions, and compare the two solutions. If the two meshes give nearly the same results, then the mesh is probably adequate. If the two meshes yield substantially different results, then further mesh refinement might be required. You should keep refining your mesh until you obtain nearly identical results for succeeding meshes.

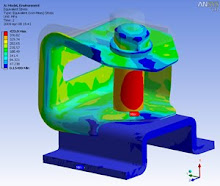

In this case, increased mesh density will be provided at junction between nozzle and header box of Air Cooler Heat Exchanger.

First, normal mesh density with 30mm length was given at the whole model. The stress intensity was given at 237.157MPa

First, normal mesh density with 30mm length was given at the whole model. The stress intensity was given at 237.157MPa And for second analysis, mesh density increased by 2 times, and the result increased at 323.598MPa.

And for second analysis, mesh density increased by 2 times, and the result increased at 323.598MPa. And after re-run the anysis with increasing the density, we obtain:

And after re-run the anysis with increasing the density, we obtain: