The analysed Molecular Dehydration vessel (SK-30-V-01 A/B) was designed to withstand a thermal cyclic operation

The analysed Molecular Dehydration vessel (SK-30-V-01 A/B) was designed to withstand a thermal cyclic operationInternal Pressure 6.89 MPa as operating pressure applied to internall surfaces. And thermal Cylclic applied at surfaces of inlet and outlet nozzle as per data shown:

The fatigue analysis was carried-out in accordance with ASME B&PV Code, Section VIII Division 2 Appendix 5 (2004 ed). As cycling loading is due to the thermal and pressure, the result shown in the table above were used for the fatigue life assessment.

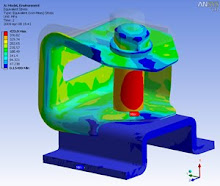

The output quantity is the stress intensity (SINT-MPa). This is calculated by the program as the largest of the absolute values of differences between principal atreses S1,S2 & S3 (where: S1>S2>S3):

The output quantity is the stress intensity (SINT-MPa). This is calculated by the program as the largest of the absolute values of differences between principal atreses S1,S2 & S3 (where: S1>S2>S3):

SINT = max {│S1-S2│,│S2-S3││S3-S1│}.

Thus, this is equivalent to Tresca stresses: S = S1-S3

The alternating stress intensity was calculated based on the maximum difference between conditions operating and stan-by operation:

The alternating stress intensity was calculated based on the maximum difference between conditions operating and stan-by operation:

Srij = 375.063 – 256.89 = 172.057 MPa

Correction Factor for increased temperature = Eo/Et

Eo = 207 GPa ( as used for S-N curve in the code )

Et = 189 GPa ( at temperature of 315 oC )

Thus, Eo/Et = 1.09

Srijcorr = 1.09 x 172.057 = 187.542 MPa

So, Sa = 0.5 x 128.809 = 93.3771 MPa

From S-N curve in the Code, number of cycles is 505 cycles (13670 years).

No comments:

Post a Comment